- Additives

- Adhesives

- Chopped strand mats

- Composite machines

- Core materials

- Epoxy resins

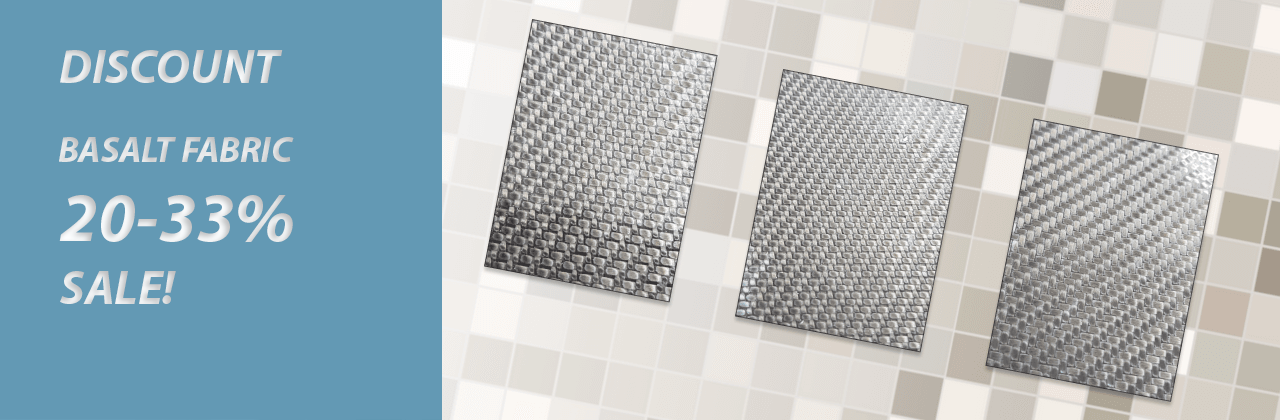

- Fabrics

- Fillers

- Gelcoats

- Grinding

- Jesmonite ® acrylic systems

- Pigments

- Polishing

- Polyester resins

- Polyurethane resins

- Release agents

- Safety equipments

- Silicones

- Tools and auxiliary

- Vacuum bagging materials

- Vinylester resins

Chopped strand mats

Két alapvető üvegpaplan típust különböztethető meg, a vágott-, vagy folytonos szálú. Az üvegpaplan rendezetlen üvegszálak egymáshoz ragasztásával (kémiai kötésű paplan), vagy tűzésével (mechanikai kötésű paplan) állíthatók elő. Az üvegpaplanok kereskedelemben megjelenő formájának egyik legjellemzőbb adata a négyzetméter tömeg, mely 100-900 g/m2 közötti, nagyobb mennyiségben a 300-, és 450 g/m2 típusokat vásárolják a feldolgozók.

Előállításukhoz 25-50 mm hosszúságú vágott üvegpászmát vagy vágott „üvegroving”-ot használnak, melyeket vágófejeken bocsátanak keresztül. A vágófejek a szálakat 20-50 mm hosszúságú darabokra vágják (műanyag erősítésnél jellemzőbb a felső határérték). A vágott szálakat mozgó szalagra terítik (véletlenszerű elrendeződés). A szálak műgyanta alapú, por vagy emulzió alapú ragasztóanyag („binder”) tartja össze, melyet permetezéssel visznek fel a felületre. A kötőanyag biztosítja az így előállított paplan egyenletes teríthetőségét, szabhatóságát, formára alakíthatóságát. A futószalagról lejövő paplan széleinek levágása és méretre vágása után a paplant feltekercselik. Így kerül kereskedelmi forgalomba. Ez ilyen módon elkészített paplanokat kémiai kötésű üvegpaplanoknak nevezik.